Your adaptive plastics partner.

Pyramid Plastics has earned a reputation as an expert in the plastic injection molding industry. From a stand alone molding solution, to end-to-end molding services, or somewhere in between, our team of engineers and molding experts are ready to help. Adapting to changing demands in the plastics industry is our strength. Pyramid Plastics can help solve all of your molding needs.

Production Molding

Our injection molding equipment is selected for its versatility and reliability, as well as its flexibility in handling a wide range of mold types and sizes. Our machines utilize the latest technology and process controls.

- Presses ranging from 40-1000 tons clamping force

- Automation/robotics for part removal/handling to maintain part quality

- Insert Molding

- Substrate and Overmolding

Secondary Operations

Pyramid Plastics offers a wide range of secondary operations so you can have the advantage of a single source provider. These include:

- Ultrasonic Welding

- Hot Stamping

- Pad Printing

- Drilling, Tapping, and Reaming

- Bonding

- Assembly and sub-assembly of components

- Packaging and Fulfillment

Quality

We are ISO 9001 certified, and adhere to stringent continuous improvement practices to maximize the efficiency of our manufacturing processes. Each project goes through a complete Advanced Quality Planning procedure that ensures proper documentation and communication flow through our various departments, throughout the duration of your project.

Click here to visit our site

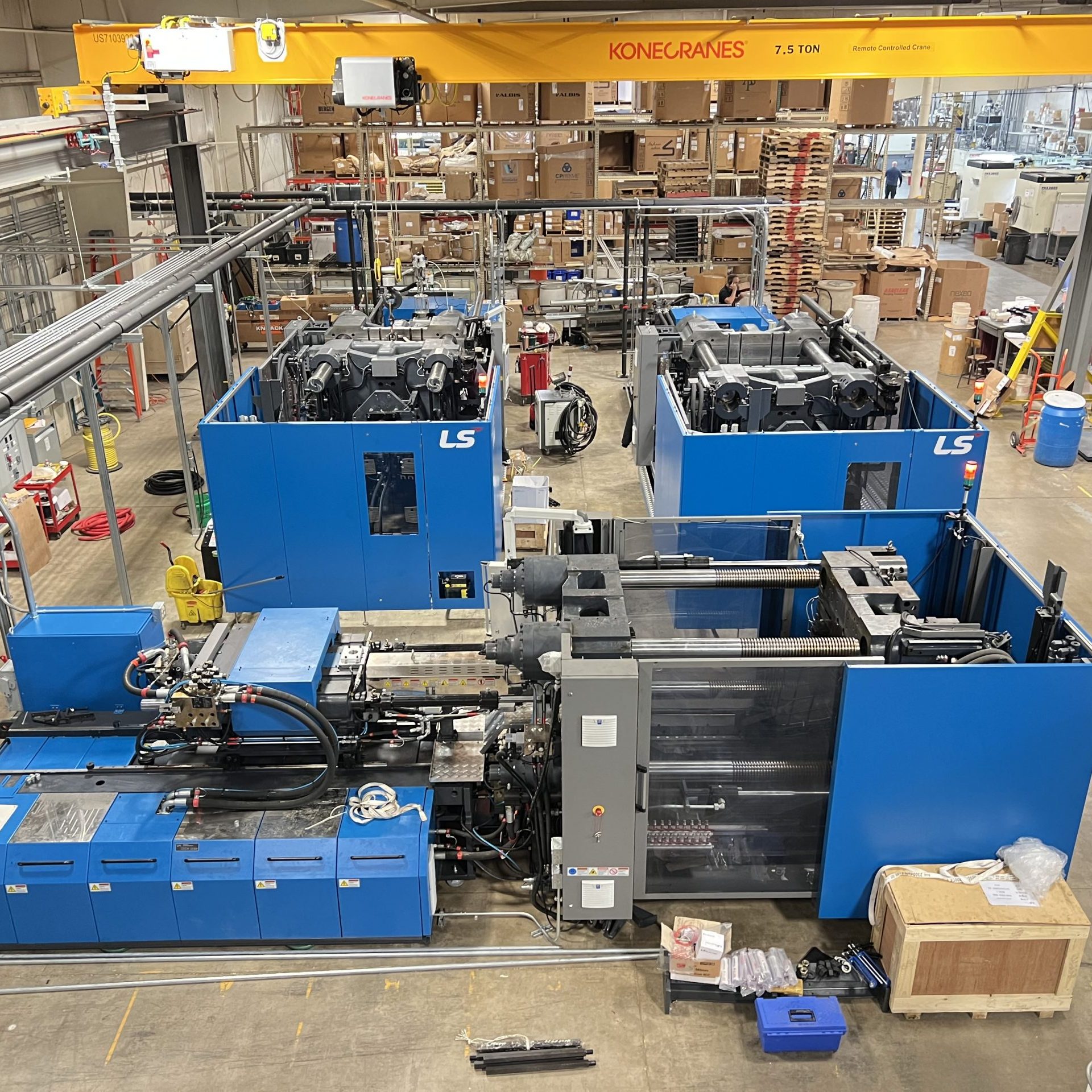

The Presses are in!

Pyramid Plastics has completed phase one of its three-year plan to expand its operations with the purchase and installation of three new injection molding machines plus additional auxiliary equipment...

Pyramid Plastics

Oil Baffle

One of our customers, a leading manufacturer of torque transfer solutions (including transmissions for OEMs like Ford and GM), presented a unique...

Pyramid Plastics