The year 2022 has been a challenging year for many. We are all trying to find the “norm” after two challenging years during the COVID pandemic. Cost of living has reached an all-time high with the current inflation rates, employers are struggling to find and keep employees, and employees are being laid-off while companies are going under. Companies have had to learn and adapt to many challenges that came with 2022. This forced company leaders to find innovative solutions to these challenges that have since become their standard practices. Pyramid Molding Group (PMG) has been evolving over the past two years. With an adaptive and innovative approach, PMG COO, Andrew Peterson, led his teams at Pyramid Plastics and Industrial Molds to great successes in 2022.

In May 2022, Pyramid Plastics introduced three new presses, two of which have a 500-ton capacity and one with a 1000-ton capacity. Adding these presses will increase capacity, improve quality, and assist our machine operators. Plastics Technology Magazine featured our newest additions in their May 2022 issue. It can be read here: https://www.ptonline.com/articles/pyramids-relentless-pursuit-of-quality.

Along with adding the new presses, Pyramid Plastics added three new robots. While many assume robots replace labor, our robots work to assist our machine operators and increase safety. Due to the size of the presses, operators previously climbed in to remove finished parts, taking up time and raising safety concerns. However, now the robots can remove the finished parts for the machine operators. “We are hoping to increase throughput without affecting labor costs 15%. The robots have also provided better parts as it has removed the human variance in cycle time, thus giving us a repeatable process every shot,” says Andrew Peterson, COO. The addition of the robots further increases our automation as can be seen here; https://www.plasticsmachinerymanufacturing.com/injection-molding/article/21277753/automation-push-propels-mold-maker-molder-forward in our feature in Plastics Machinery Manufacturing Magazine.

In October 2022, Industrial Molds welcomed a shiny, new HAAS machine to the parts center with the announcement of adding two more in early 2023. “New machines have increased the departments capacity by 50%. This will allow for shorter delivery times by keeping more work in house and just having more throughput bandwidth,” says Andrew Peterson, COO.

departments capacity by 50%. This will allow for shorter delivery times by keeping more work in house and just having more throughput bandwidth,” says Andrew Peterson, COO.

The national labor shortage has affected hundreds of industries and thousands of companies thus delaying lead times or stopping manufacturing all together. Realizing this issue early on allowed the PMG team to rethink how to go about recruitment and retention. After years of using staffing agencies and temporary workers, PMG switched their approach by hiring a corporate recruiter and only offering direct hire positions. This change has increased headcount from 98 employees to 110 while also greatly increasing employee retention. Our efforts were noticed by Plastics Business Magazine, and we were happy to share our insight here: https://bluetoad.com/publication/?m=18060&i=768356&p=12&ver=html5. Retention has become a top priority and we strive to make all employees feel appreciated through employee parties, outings, giveaways, and recognitions for perfect attendance and other achievements.

A main contributor to our increased retention is a value that has run deep with PMG for decades and that’s a focus on growing our people.

“When you grow your own, you can hire for fit, attitude and aptitude, not just skill set. We can train the rest,” says Tim Peterson, President. Currently four machine operators at Industrial Molds are enrolled in the Rock River Valley Tooling and Machining Apprenticeship program. Industrial Molds fully sponsors this program while the students stay employed full-time. Upon completion of the program, Lorenzo, Wyatt, Connor, and Justin will have earned their journeyman’s card and associate degree. We are also excited to have our first high school apprentice! This student is from the Rockford Public School district and is training in our polishing department. This is a great opportunity for the student to earn hands-on experience in his field of interest. “The high school apprentice has welded his first couple of real jobs with success,” says Kris Grey, Industrial Molds Expeditor.

Giving has been on the forefront of PMG owners’ minds since the company’s first inception in 1968. Continuing to give back to our

community is still a top-priority but we want to better focus our giving efforts and build solid relationships with our beneficiaries, so we founded the PMG Gives Foundation. Comprised by a committee of four PMG employees, PMG Gives donated a percentage of yearly profits to multiple local nonprofit organizations whose missions align with our values. Our first PMG Gives donations were awarded in Q4 2022 to Carpenter’s Place Outreach Center, Fatherhood Encouragement Project, United Way, and Pregnancy Care Center of Rockford. We plan to continue supporting these organizations and others for many years to come. We are eternally grateful for the good they do for our community.

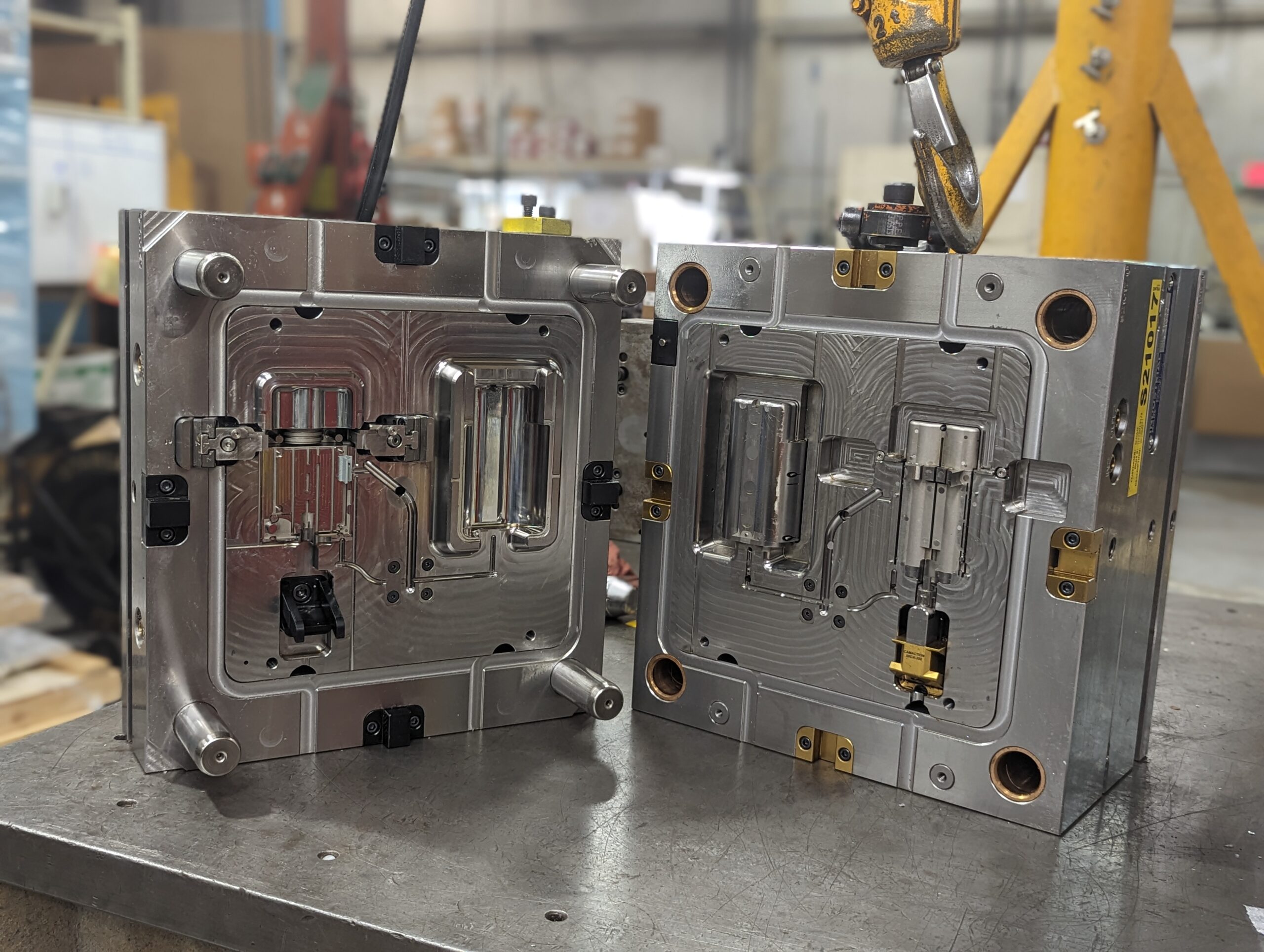

2022 came with many challenges and changes but our team at PMG stepped up to the plate to make 2022 a year of adapting, improving, and evolving. The synergy between Pyramid Plastics and Industrial Molds continues to grow stronger as 20% of Industrial Molds sales last year came from Pyramid Plastics. This relationship gives our customer peace of mind, knowing they have a solution if they need an urgent tooling modification or repair. We are thankful for our amazing team and look forward to 2023 being another great year!

Recent News

Join Us at Booth 2123 at MD&M Minneapolis – October 16-17!

2024 PMG Employee Golf Outing

Pyramid Molding Group Proudly Announces COO, Andy Peterson, as New Vice President of the American Mold Builders Association Board of Directors

PMG Helps Frame the Future